1. Custom Made CNC system, economical and reliable.

2. Comes with 5C collet chuck for faster workpieces clamping.

3. 6-station gang tool plate provides customer a fast, simple and economical turning method for small workpiece.

4. High-quality cast iron bed and HIWIN linear guide ensure high rigidity, superior resistance and long life.

5. The main electrical components are from ABB, ensure the high reliability of lathe's electrical system.

6. One piece of high-strength glass, without sheet metal to reinforce, is place on the front door of CKG-32, ensures that the operator can clearly see the working conditions inside the lathe.

■ Adopt TAIWAN technology, designed by TAIWAN engineer, most parts adopt GERMANY/JAPAN/TAIWAN brand.

■ Adopt 30°integral slant bed design, high rigidity, good machining flexibility, easy for chip conveying, convenient operation.

■ Adopt modularization design, has strong extended function, easy for various especial configuration choice, such as tool setter, VDI tool plate, Robot etc.

■ Adopt high-class resin sand cast iron, after aging treatment and FEA analysis, small distortion, good torsional strength, good heat stability.

■Adopt high precision integral spindle unit, spindle motor adopt high performance servo motor, big output torque, high speed ,wide adjustment range

■ Adopt high precision pre-stretched ball screw, coupled with feeding motor directly by linkager , no gap ,high transmission rigidity, can realize μ class precise turning.

■ Adopt high precision wide linear guideway, high rigidity and long using lifespan, fast moving speed, good accuracy holding, suitable for heavy loading and precise machining

■ Adopt SERVO tool turret ,fast tool changing, good repeatability ,high efficiency.

■ Adopt two types lubrication: Spindle bearings and ball screw bearings adopt Germany KLUBER high speed long acting lubricating grease, maintenance-free. Ball screw and guideway adopt automatic centralization lubrication

■ Adopt LED working lamp, energy conservation, long using lifespan

■ Adopt high strength tempered glass to protect operator

■ Super compact structure, big inside space, modern appearance

■Can mount right-setting or back-setting chip conveyor, strong chip conveying capacity

Standard configuration:

●SIEMENS 808D ADVANCED CNC controller

●X/Z axes driver&motor: SIEMENS servo

●Spindle: servo motor& driver

●Hydraulic chuck

●SERVO tool turret

●Hydraulic Tailstock

Optional configuration:

●SIEMENS 828Di/FANUC 0i TF CNC controller

●Automatic chip conveyor

Product Information

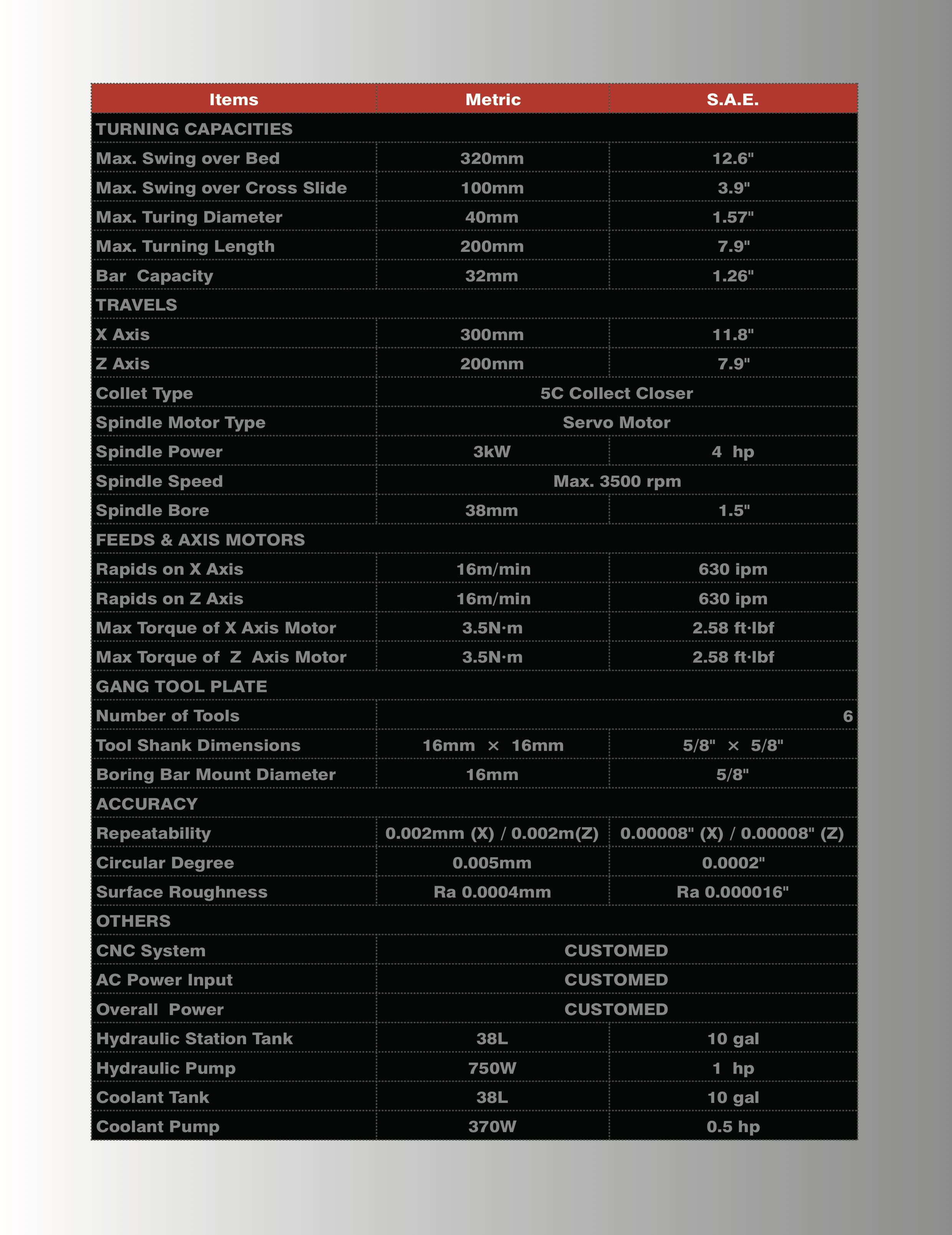

Technical Details

FAQ:

1.Q: How is the delivery?

A:For standard configuration, it's usually 30 days after down payment.

2.Q:How is the after-sales service?

A: Our products has one year warranty, and a strong team of engineers to support after-sales service.

3.Q:Are you a trading company or manufacture?

A:In time is a professional manufacturer, and your order will be controlled from very beginning to the last.Solution suppiler:

Ningbo junfa CNC Equipment Co. Ltd.

Welcome to inquire and visit our company!We are looking forward to serving you!